DryFiciency consortium welcomes Viking Heat Engine as an official new partner to the project

To reach the goals outlined in the Paris Agreement, it will not be enough to ramp up the production of renewables. The world will also need to use a lot less fossil fuels and become much better at utilizing the energy it already produces to avoid an increase in global temperatures by 2 °C.

The DryFiciency project, led by the Austrian Institute of Technology and funded by the European Union through the Horizon2020 program, aims to develop three industrial heat pump systems to transform heat that’s currently going to waste into high-temperature energy that can be used in industrial processes, such as drying and dehydration. It’s estimated that such low-carbon systems can reduce as much as 80 % of the energy currently used in industrial drying processes today.

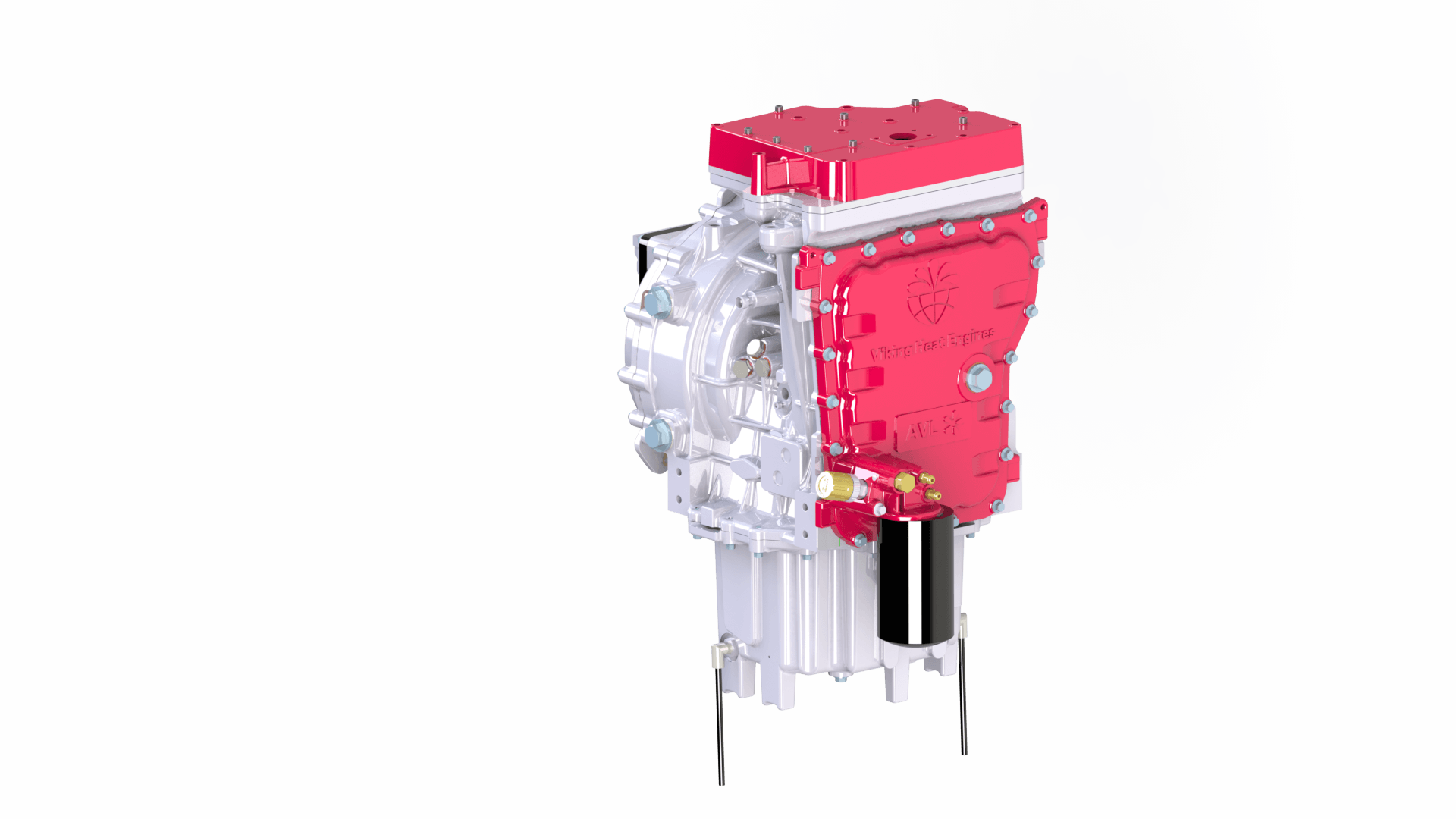

Needless to say, the urgency of implementing such systems is massive as the global situation is getting more acute by the hour. But developing any type of system from scratch takes time, even if you have the best partners in the world. Viking Heat Engines was therefore happy to join the consortium and provide AIT and its partners with a compressor specially developed for industrial use that can easily be integrated into any heat pump system and reach the required temperatures. This was not only a chance for the green tech company from Norway to showcase its technology to some of the biggest heat pump producers in the world and get an independent evaluation from one of the most esteemed research institutes in Europe. It was also a chance to make a difference in reducing CO2 emissions from European industry – something that’s supports its vision: to accelerate the world’s energy transition towards a sustainable future.

“The piston compressor developed by Viking Heat Engines is a perfect match in achieving the goals of the DryFiciency project as it is designed to provide operating temperatures up to 160 °C,” says Thomas Fleckl, Head of Competence Unit “Sustainable Thermal Unit” at AIT. “Viking Heat Engines also uses the same novel and environmentally friendly refrigerant OpteonMZ developed by Chemours as the DryFiciency project and brings in valuable experience from developing its own industrial heat pump system.”

Reducing emissions from industrial drying in Europe

With 12 to 25 % of the national industrial energy consumption attributed to industrial drying in developed countries, drying and dehydration are among the most energy-intensive and wide-spread processes in many industrial sectors due to the use of fossil fuels and minimal or no utilization of waste heat streams. Three manufacturing segments are addressed in the DryFiciency project, namely brick, pet food and starch production. The outcomes from the project will also be of major relevance to several other energy-intensive industries, such as the pulp and paper industry.

Viking Heat Engines’ technology will be implemented in one of the closed-loop heat pump systems to be demonstrated in the ceramic industry for green brick drying at Wienerberger, the world’s largest producer of bricks and number one in the clay roof tiles market in Europe. Wienerberger operates approximately 200 production sites in 30 countries in Europe, North America and India, and employs about 15,000 staff worldwide.

“A successful demonstration will open up a substantial business opportunity for Viking Heat Engines alone at Wienerberger,” says Fleckl “The technology can also be used in a number of other energy-intensive industries, such as pulp and paper, chemical/petrochemical, non-ferrous metals as well as the food and beverages industry. We look forward to help bring this technology into commercialization and demonstrate to the world what a difference a heat pump system can make.”

Author: Torunn Hansen-Tangen and Mattias Nilsson, Viking Heat Engines

Contact: norway@vikingheatengines.com, Tel: +47 38 10 41 00

Web address: www.vikingheatengines.com

Project Coordinator

Veronika Wilk

AIT Austrian Institute of Technology GmbH

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 16 years 4 months 8 days 15 hours 5 minutes | These cookies are set via embedded youtube-videos. They register anonymous statistical data on for example how many times the video is displayed and what settings are used for playback.No sensitive data is collected unless you log in to your google account, in that case your choices are linked with your account, for example if you click “like” on a video. |

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| yt-remote-connected-devices | never | These cookies are set via embedded youtube-videos. |

| yt-remote-device-id | never | These cookies are set via embedded youtube-videos. |