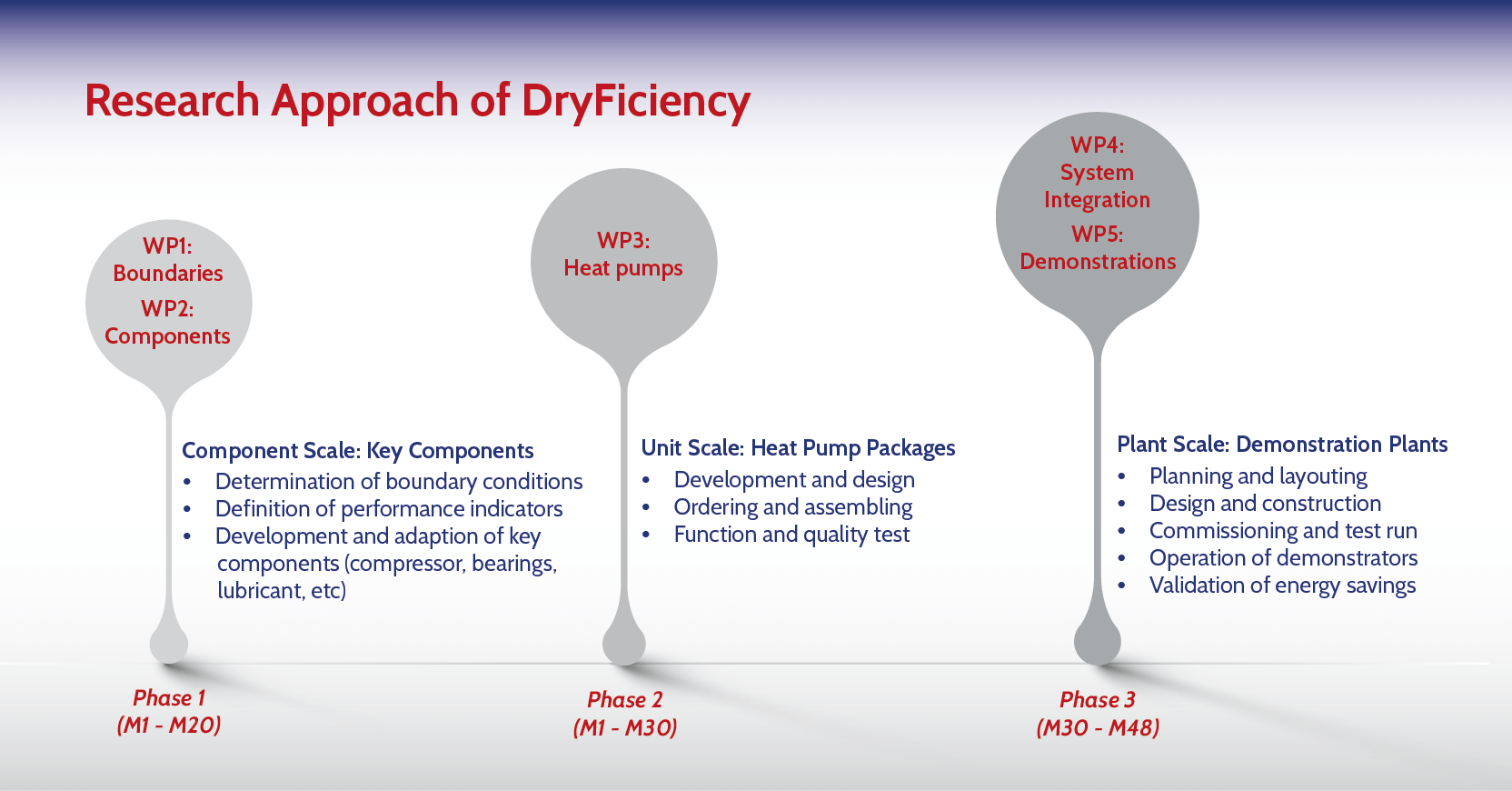

Phase 1: Key components

WORK PACKAGE 1 BOUNDARIES

The main task of this work package is to assess all necessary input and boundary conditions of the industrial processes, where the heat pumps are integrated. Performance indicators are elaborated to be used for validation of the demo plants in WP5.

WORK PACKAGE 2 COMPONENTS

Work Package two is dedicated to adaptions on component level for both, the components to be used in the closed loop and the open loop heat pump technologies. This includes in particular research work to find a compatible refrigerant/ lubricant mixture for the Bitzer compressor to be used in the closed loop heat pump technology. For the open loop cycle, a lubrication/ oil free turbo-compressor will be developed and validated.

Phase 2: Heat Pump Packages

WORK PACKAGE 3 HEAT PUMPS

Phase 3: Demonstration plants

WORK PACKAGE 4 SYSTEM INTEGRATION

In this work package the integration of the heat pumps at the industrial system is elaborated. The integration layout of the demonstrators is developed in accordance with the quality and safety standards to be applied at each demonstration site, infrastructure compounds are dimensioned, designed and ordered. Commissioning of the demonstration plants is also carried out within WP4.

WORK PACKAGE 5 DEMONSTRATORS

The end users will operate the demonstration heat pump systems in addition to their regular production facilities under real industrial production conditions. All relevant data will be recorded and regularly analysed to validate the targeted energy savings and to evaluate the key performance indicators defined.