OPEN LOOP HEAT PUMP SYSTEM IN DRYFICIENCY

Open loop heat pump systems also known as Mechanical Vapour Recompression (MVR) systems use water as refrigerant in steam drying processes. Water as refrigerant is easily available, non-toxic and represents no environmental hazard.

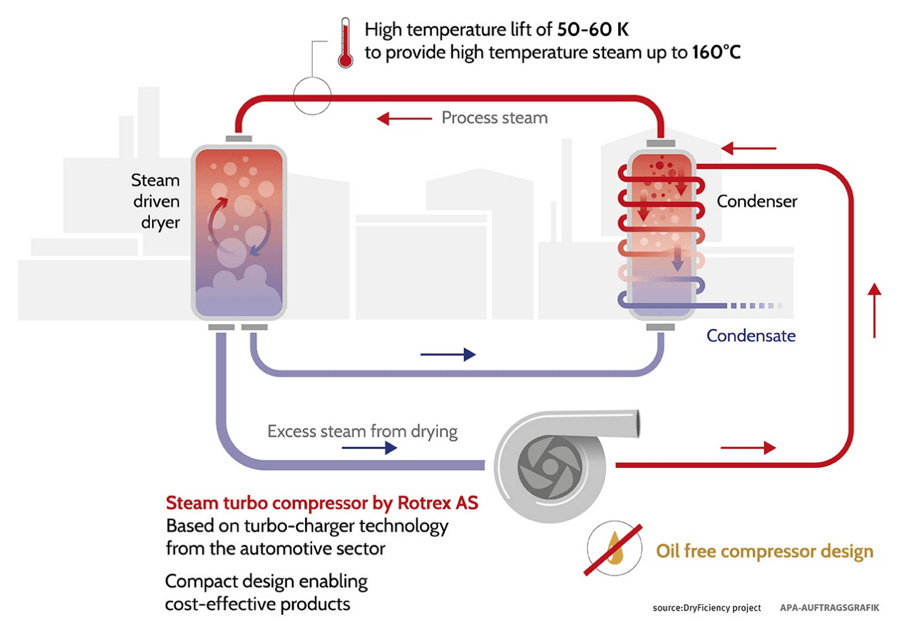

In steam drying processes, goods are dried in a steam atmosphere. The process steam is circulated and reheated by a natural gas burner. The water removed from the product is present in the form of excess steam. Usually, the excess steam cannot be used further because there is no heat demand at this temperature and it is therefore wasted. MVR systems allow the use of the excess steam. Compressors increase the pressure level of the surplus steam to condense it at higher temperatures. A separate evaporator is not required, as the dryer acts as such.

The open loop heat pump system developed by the DryFiciency consortium uses advanced, low-cost, turbo-compressor technology originating from the automotive sector. They were further developed to reach condensation temperatures of up to 160°C at a combined pressure ratio of 6 when compressing steam over two stages. In the condenser, the hot excess steam reheats the process steam of the dryer. Thereby, the natural gas burner can be replaced. Read more on this system here.

The following graph shows the working principle of the open loop heat pump system with its innovative component, the oil-free steam turbo-compressor technology developed by Rotrex, integrated in a steam drying process.