Compressors from Viking Heat Engines and Bitzer – specially engineered to reach up to 160 °C – have been delivered to an experienced Austrian heat pump manufacturer and work is underway to build the first industrial, high-temperature heat pump systems to be installed at DryFiciency’s demo partner sites.

AMT Kältetechnik GmbH, an engineering and construction company of industrial and commercial heating and cooling solution, was awarded the contract to build the two novel closed-loop heat pumps by the DryFiciency consortium in October 2018 and is set to deliver the systems by March 2019.

The heat pumps will be installed at Wienerberger AG, the world’s largest producer of bricks and number one in the clay roof tiles market in Europe, and Agrana Starch GmbH, a specialist in processing high-quality agricultural commodities.

Both companies want to reduce their dependency on fossil fuels used in their energy-intensive drying processes. At Wienerberger, the heat pump will make use of available waste heat and boost it up to 160 °C to heat the air that dries the bricks. The heating capacity of the demonstrator will be around 400 kW.

At Agrana, the heat pump will have the same heating capacity (400 kW), which is about 10% of the heat demand of the starch dryer, and a temperature range between 110 to 160 °C.

It is estimated that about 75% of the CO2 emissions and 80% of the end energy consumption can be avoided using these heat pump systems instead of the current natural gas burners.

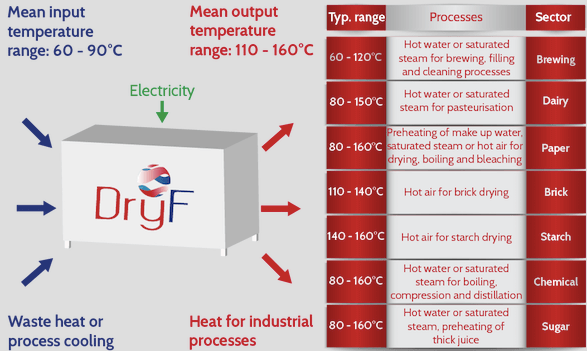

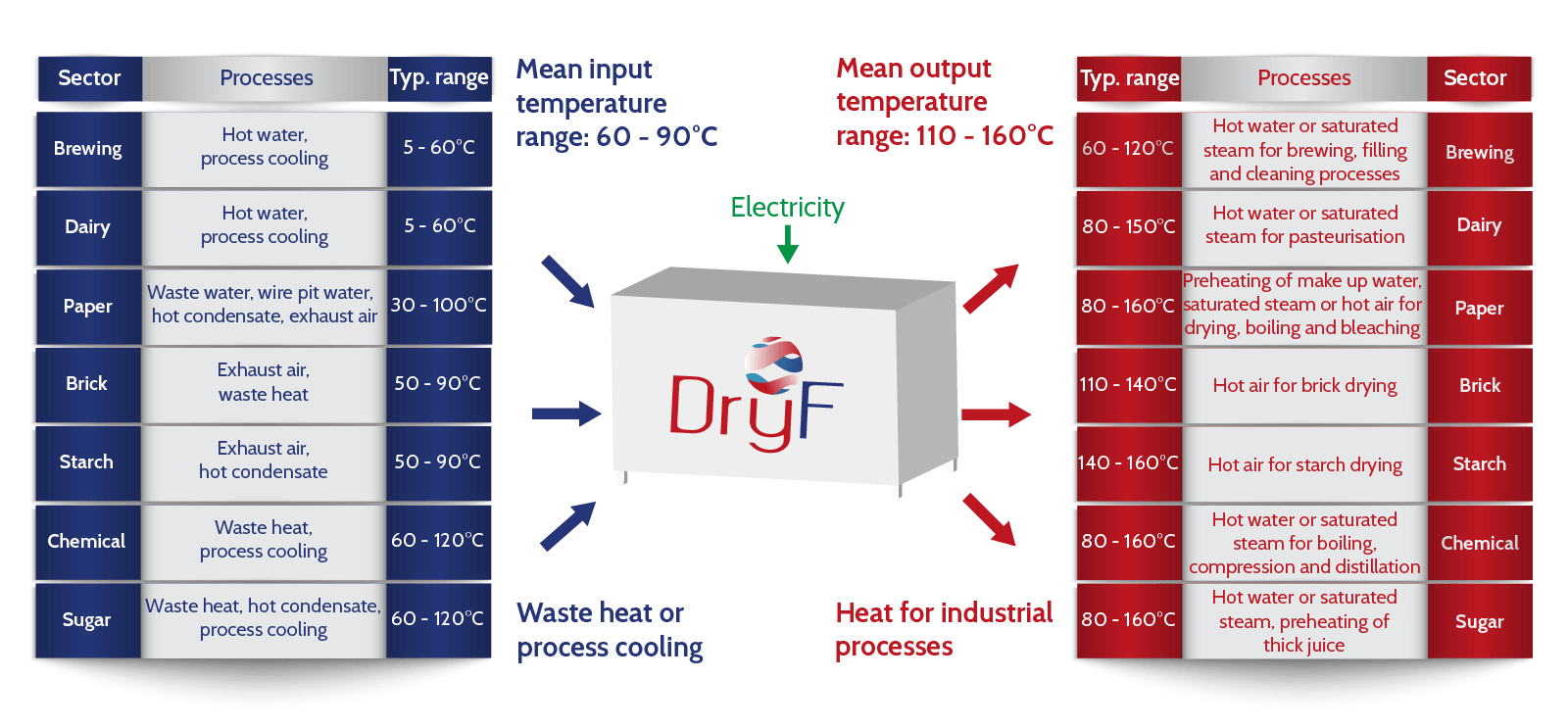

While the DryFiciency project mainly addresses the brick and food industries, the heat pumps can be used by a wide range of industries wishing to make their processes more energy efficient.

Examples of other industries and processes where the heat pumps would be ideal include steam production in the pulp and paper industry; drying, sterilization and pasteurization in the food and beverages industry; paint drying and moulding in automotive industry; and thickening, cooking and distillation in chemical industry (see a more detailed application overview in the illustration below).

Unique compressor technologies

Apart from being able to reach the highest temperatures of up to 160 °C, the compressors from Viking Heat Engines and Bitzer have many novel features.

Viking Heat Engines’ piston compressor is based on a proven, heavy-duty design developed in collaboration with the world's largest engine design company, AVL. The compressor has been engineered to operate at very high internal temperatures and pressures (up to 215 °C). It's compatible with all common refrigerants of the 3rd and 4th generations (e.g. HFOs) and can cover the whole temperature range (0-160 °C) by just switching refrigerant.

Some of its key features include:

BITZER’s screw compressor, on the other hand, is based on the company’s HS compressor series, which was adapted to fit the requirements of high-temperature applications with condensing temperatures up to 160°C. HS compressors have proven to be efficient, robust and durable and are compatible with a wide range of refrigerants. The semi-hermetic compressor has a two-shaft rotary displacement design with a high efficiency profile geometry.

Some of its key features include:

Authors:

Torunn Hansen-Tangen and Geir Robstad, Viking Heat Engines

Edited by:

Annemarie Schneeberger, AIT Austrian Institute of Technology

Project Coordinator

Veronika Wilk

AIT Austrian Institute of Technology GmbH

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 16 years 4 months 8 days 15 hours 5 minutes | These cookies are set via embedded youtube-videos. They register anonymous statistical data on for example how many times the video is displayed and what settings are used for playback.No sensitive data is collected unless you log in to your google account, in that case your choices are linked with your account, for example if you click “like” on a video. |

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| yt-remote-connected-devices | never | These cookies are set via embedded youtube-videos. |

| yt-remote-device-id | never | These cookies are set via embedded youtube-videos. |