During the recent EHPA and DryFiciency seminar towards greener energy, Michael Bantle Senior Researcher SINTEF Energy Research, explored the key drivers towards the increased acceptance of heat pumps (HP). Specifically, in Scandinavia HP experience a high acceptance, with heat pumps becoming the "standard" solution for building heating as well as several industry segments. This has also resulted in a number of Start-Up companies & projects for High Temperature Heat Pumps (HTHP).

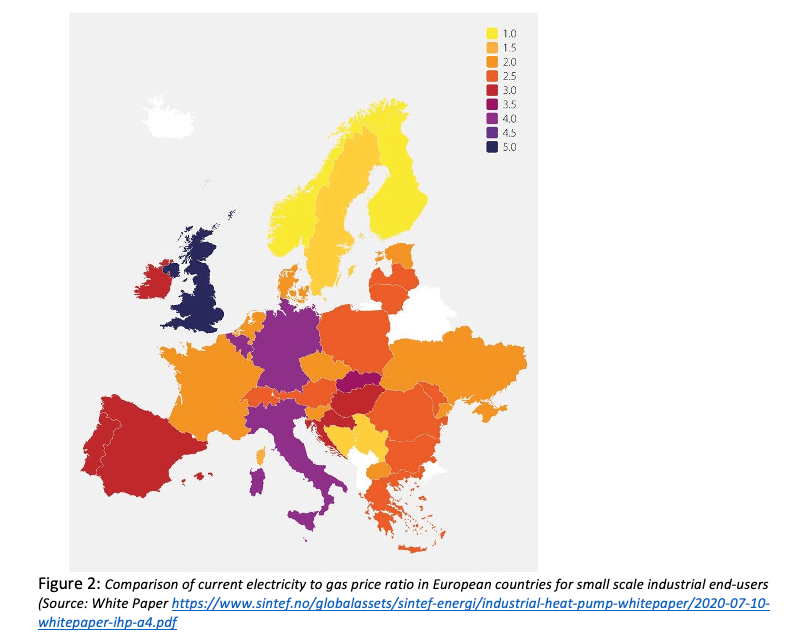

One of the major drivers for this high acceptance and demand for HP can be seen in the attractive energy price ratio in Scandinavian countries. Price difference per kWh electricity vs. fossil fuel is virtually non-existent. In many other European countries electricity prices are still far more expensive than fossil fuels resulting in a far lesser uptake of electricity applications such as heating, industrial drying and cooling. The two charts show clearly where the markets have to go. A de-carbonized future requires increased use of electricity, and efforts need to be made on all levels to systematically reduce the price of (renewable) electricity. Coupled with efficiency of applications and systems the market for heat pumps is only going to develop further encompassing new processes and higher temperatures.

A number of efficiency projects are already underway that utilize the attractiveness of heat pumps. One industrial heat pump example in the Norwegian dairy industry combines heating and cooling aspects in dairy production saving 5 GWh / year, which equals to a reduction of almost 45% in primary energy. “Looking at the situation in Norway today we realize that Norway today, is like looking into the future at Europe in 20 years.“ says Bantle. “These benefits of reducing greenhouse gas emissions by renewable energy sources to practically zero as is being done in Norway today can be replicated in rest of Europe”.

Other projects underway also look at the vast business opportunity for waste heat recovery in industrial processes worldwide. This is also demonstrated in the DryFiciency project. In this Horizon2020 project 11 partners are upgrading idle waste heat streams to process heat streams up to 160°C. Key elements of the solution are three advanced high temperature vapour compression heat pumps comprising two closed loop heat pumps for air drying processes at Wienerberger and Agrana, and one open loop heat pump for steam driven drying processes in Norway at Scanship/ Lindum waste management facility. The challenges included a number of components never before tested under these high temperature parameters including compressors, lubricants and refrigerants. Designs and prototypes had to be designed to account for the integration in industrial processes, the design of refrigerant cycles and the process control and monitoring.

The results from commissioning and demonstration show that these efforts are well worth the research and investment as the heat pumps in action show clear rewards in terms of energy efficiency, waste heat utilization, Co2 reduction and GHG emissions. So, with Norway leading the way towards heat pump integration today with other European countries needing to follow, it is clearly Norway, and not no-way of not investing into heat pumps.

About Dr Michael Bantle, Senior Researcher, SINTEF Energy Research

Michael Bantle is a Senior Researcher at SINTEF Energy and is focusing on the development of high-temperature heat pumps and their integration into the process industry. The main motivation behind his engagement is to decarbonize thermal processes, whenever possible, but also to reduce primary energy demand.

Project Coordinator

Veronika Wilk

AIT Austrian Institute of Technology GmbH

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 16 years 4 months 8 days 15 hours 5 minutes | These cookies are set via embedded youtube-videos. They register anonymous statistical data on for example how many times the video is displayed and what settings are used for playback.No sensitive data is collected unless you log in to your google account, in that case your choices are linked with your account, for example if you click “like” on a video. |

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| yt-remote-connected-devices | never | These cookies are set via embedded youtube-videos. |

| yt-remote-device-id | never | These cookies are set via embedded youtube-videos. |