The DryF high-temperature open loop heat pump demonstration aims to generate heat of 155°C. Temperatures of 110°C to 155°C are required to be able to remove water from bio sludge in an evaporation process. The technology is driven by a two-stage turbo-compressor technology developed by the Danish automotive technology company Rotrex A/S.

Rotrex is the inventor and patent owner of the planetary traction drive, used in superchargers for automotive OEM, OES and aftermarket companies, Air pumps for Hydrogen Fuel Cells, and various research purposes, worldwide. This type of compressor technology was also used and enhanced for the DryFiciency project in order to produce a cost-efficient and highly efficient system for industrial drying industries.

Overall, for all standard products made by Rotrex, is compression of ambient air which is significantly different than compression of superheated steam. Super-heated steam with extreme operating temperatures, H20 and industrial durability demands, is a challenging task to complete.

Rotrex’s Head of Operations and Project Manager Søren Schmidt, said that implementing demonstrations derived from this pioneering technology involved highly technical challenges to ensure adequate performance, efficiency and reliability and fulfilling the requirement template for the DryF H2020 project. During the first work package of DryF, the specifications were determined which set the design criteria for the turbo steam compressors. Because of a demand for a total compression ratio of up to 1:6, it was deemed necessary to add multiple compression stages. Rotrex compressors uses so called “centrifugal” compressor technology, which is the most efficient compressor technology and enables unmatched total system efficiency. However, a single stage compressor can reach up to 2,5-2,8 to remain durable and comply with industrial demands. Early concept was a three-stage system with a total of six compressors.

As the project progressed, the six compressors decreased to a total of only two compressors, for a dual-stage setup. Each compressor designed specifically for its specific stage in order to maximize efficiency and performance.

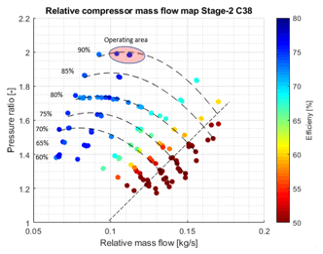

The compressors were tested in a steam atmosphere at SINTEF Energy Lab, according to the 2-stage configuration shown above. The goal was to create the compressor maps which relates the compressor speed, mass flow, pressure lift and isentropic efficiency for each impeller. Also, the strategy for desuperheating in between the compressor stages was verified. The testing and results were satisfactory for Scanship, and the compressors are currently being tested on their open-loop industrial steam dryer at Lindum.

The Horizon 2050 EU roadmap specifies an eventual goal of aiming to dry materials such as iron, steel and non-metallic minerals at heats of up to 400°C. These measures are part of encouraging low carbon technology solutions by capturing heat technology, and to use it as a renewable source of energy. Offering heat pump technologies at a reduced CAPEX rate, including integrated cost-effective heat pump process solutions, and installation, are part of the goal to speed up market diffusion.

Project Coordinator

Veronika Wilk

AIT Austrian Institute of Technology GmbH

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 1 year | This cookies is set by GDPR Cookie Consent WordPress Plugin. The cookie is used to remember the user consent for the cookies under the category "Analytics". |

| cookielawinfo-checkbox-necessary | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Others". |

| cookielawinfo-checkbox-performance | 1 year | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 1 year | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| CONSENT | 16 years 4 months 8 days 15 hours 5 minutes | These cookies are set via embedded youtube-videos. They register anonymous statistical data on for example how many times the video is displayed and what settings are used for playback.No sensitive data is collected unless you log in to your google account, in that case your choices are linked with your account, for example if you click “like” on a video. |

| IDE | 1 year 24 days | Used by Google DoubleClick and stores information about how the user uses the website and any other advertisement before visiting the website. This is used to present users with ads that are relevant to them according to the user profile. |

| VISITOR_INFO1_LIVE | 5 months 27 days | This cookie is set by Youtube. Used to track the information of the embedded YouTube videos on a website. |

| YSC | session | This cookies is set by Youtube and is used to track the views of embedded videos. |

| yt-remote-connected-devices | never | These cookies are set via embedded youtube-videos. |

| yt-remote-device-id | never | These cookies are set via embedded youtube-videos. |